Academic support for AR educational needs – an AREA survey

Overview

A key component of the AREA’s goal is to help accelerate the growth of a comprehensive AR ecosystem. Our Educate initiative advances this goal by seeking to further engage with academic institutions to provide feedback on how they can help equip the graduates of tomorrow with the AR skills needed to positively contribute to the workforce.

Earlier in 2020, the AREA, together with our academic members, conducted a survey to capture industrial perspectives on both educational needs for future graduates, as well as an assessment of the current state. In this editorial blog, we’d like to share the main findings of the survey results.

Summary

The survey highlighted several key results:

- There is a high level of agreement, across multiple industries, that AR is either in mainstream use now or will be in the next few years

- Industry views educating students in AR as important,

- The business aspects of AR, rather than deep technical knowledge, are deemed to be of higher importance.

- Recent graduates are typically under-skilled in AR.

- Industry is willing to engage with academia to help address these challenges.

Survey respondents

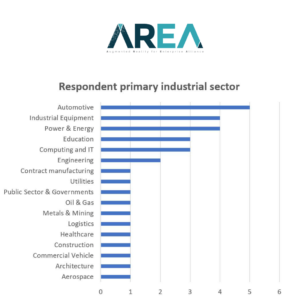

The survey attracted 43 respondents, with a good mix between those providing AR solutions and services (58% of respondents) and those using them (42% of respondents). Perhaps more importantly, we captured perspectives from a wide range of industries, as shown in Figure 1, with the highest levels of response from the automotive, industrial equipment and power and energy industrial sectors.

Figure 1 Primary industrial sector of survey respondents

AR adoption now and in the future

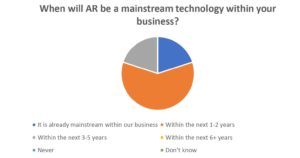

When asked “When do you see AR becoming mainstream in your business?”, 20% of our survey respondents stated that AR is already mainstream in their business. Another 60% of respondents believe that AR will become mainstream within 1-2 years, with the remaining 20% suggesting a longer timescale of 3 to 5 years, as shown in Figure 2. Perhaps unsurprisingly, no respondents chose “never.”

Figure 2 Perspectives of when AR will become mainstream

Where should academia focus on educating students?

Our next question, perhaps the most significant of the survey, requested views on where academia should focus on educating the graduates of tomorrow. Respondents were asked to rate each of the following graduate attributes from 1 (least important) to 10 (most important):

- Deep technical familiarity with the underpinnings and principles of AR software or hardware

- A strong theoretical foundation of how AR technologies can benefit industry and society

- Practical experience developing (coding, authoring) AR applications

- Practical experience and understanding how to apply AR technology to “real-world” business challenges

- Familiarity with using AR as a tool in business settings and use cases

- An understanding of the business aspects of AR (costs and cost savings, ROI, safety, security, privacy)

- Awareness of global and industry trends in the adoption and usage of AR

- Experience with the human factors, ergonomics or user interface design of AR solutions

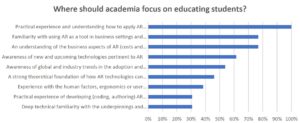

The distilled answers to this question are shown in Figure 3. We order the answers by the number of respondents that suggested a value of between 8 and 10 (inclusive) for each educational need.

The responses clearly show that the “business-oriented” aspects of AR are believed to be more important than the underlying technologies and ergonomics. 75% of all respondents ranked the business aspects with scores of 8 to 10. In particular, 100% of respondents scored the educational need “Practical experience and understanding how to apply AR technology to ‘real-world’ business challenges” with a score of 8 to 10.

Perhaps this reflects an industrial requirement that graduates better understand how to apply AR technologies rather than the ability to build such technologies.

As such, it is clear that the results of our survey highlight a need for academia to equip the graduates of tomorrow with the skills addressing how to apply AR to business challenges and how to quantify and qualify business value, cost and other practical considerations.

Figure 3 Where should academia focus?

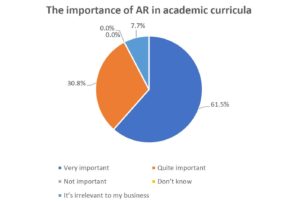

The importance of AR in university curricula

When asked “…how important do you believe it is, that academic institutions should include AR in their curricula?”, the answers were as shown in Figure 4.

61.5% of respondents answered, “Very important.” Interestingly, 92% of respondents deemed academic support for AR as either “Very” or “Quite” important.

Figure 4 The importance of AR in university curricula

If these answers reflect a sentiment shared across industries, then there is a clear message to academic institutions to include aspects of AR in various university courses of study.

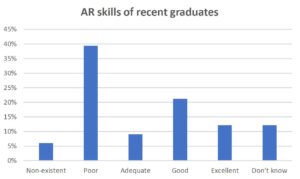

AR skill levels of recent graduates

We then asked respondents to rate their impressions of the AR skills and experience of recent graduates. The results are shown in Figure 5. Of these results, 42.4% of respondents believed that the skills and experience were either adequate, good or excellent. More worryingly, 45.5% of respondents were of the opinion that the AR skill levels were either poor or non-existent.

The question did not dig into how the skills were acquired (e.g., by way of new-hire training) but nevertheless, the answers clearly represent a set of mixed opinions of how well-equipped recently graduated staff are to embrace and apply AR within the workplace.

Figure 5 Perceptions of AR skills of recent graduates

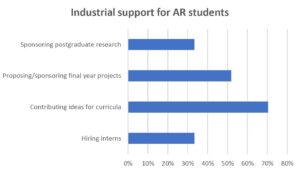

Industry’s willingness to engage with academic institutions

The last questions of the survey attempted to measure the level of interest expressed by industry to engage with the education process. Figure 6 illustrates an encouragingly high level of willingness to get involved with students in various ways with 70% of respondents willing to propose ideas for course curricula.

Figure 6 Ways in which industry would support student education

There are some clear indications that industry wants to engage further with academia whether it be by sponsoring postgraduate research, suggesting final year projects, or simply suggesting ideas for course curricula. Perhaps more notable from the point of view of the students, there is clearly an appetite for hiring interns with AR skills.

Finally, when asked if they would be willing to discuss their answers further with AREA staff, 58% of respondents expressed a willingness to do so. We are grateful for their offers to engage further.

Conclusions

Whilst accepting that a response count of 43 is perhaps not statistically significant, the survey results obtained do highlight some key messages for the academic community:

- The data captured by this survey is from a wide range of industries.

- 80% of respondents believe that AR is either in mainstream use now or will be in 1 to 2 years.

- Industry views AR education as important.

- Academic courses should equip students with the knowledge of how to apply AR to business use cases along with other business aspects such as ROI and cost.

- The majority of respondents believe that recent graduates are under-skilled in AR

- Industry is willing to engage with academia to help improve this.

The message is clear: there is a need for AR in academic courses and industry is willing to engage to help make it happen.

Acknowledgements

The AREA team wishes to thank all of those who participated in this survey.

We gratefully acknowledge the assistance of Professor Barbara Chaparro, Embry-Riddle Aeronautical University, in the construction of this survey.