In a tight labor market, AR helps distribute knowledge and skills in the field

Tesla, incidentally, trialed Google Glass but has since gone on to patent its own AR headset system, a testament to the growth of AR and wearable computers even in manufacturing.

The technology is hitting at just the right time. Some 10 million manufacturing jobs will likely be needed in the coming decade, yet many of those will likely go unfilled due to a massive skills gap, according to Deloitte and the Manufacturing Institute.

Augmented reality, which is still trying to find its stride in the enterprise, help by scaling on-the-job knowledge transfer. That could come in the form of everything from schematic overlays to help workers in the field to hives of “old hand” experts in a central location who can guide workers on the job.

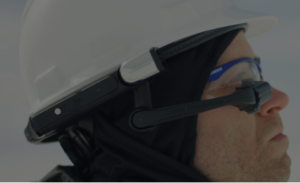

The race to provide the technology has been heating up, with companies like Vuforia and Google competing to provide headsets for the next industrial revolution, one aided by automation but in which humans still feature centrally. As in most technology categories, most of the players have competed to provide the most feature-rich hardware, but RealWear has taken a different tack.

“The augmented reality enterprise market has experienced a great deal of hype, but long-term, real-world solutions have been thin on the ground,” said Tom Mainelli, IDC Group VP of Devices and AR/VR. “RealWear smartly recognized the need for a no-nonsensehead-mounted display and has delivered no-frills products that help frontline workers to get their jobs done more safely and efficiently.”

So far RealWear has shipped 15,000+ units, making it a preferred technology provider in its class and attracting interest from big investors like Qualcomm Ventures.

“RealWear has experienced strong growth and is well positioned to become a leading platform for connected workers everywhere,” said Richard Tapalaga, Director, Qualcomm Technologies, Inc. and Investment Director, Qualcomm Ventures.

In the last 18 months the company has added 1,300 enterprise customers, and its app ecosystem has more than 120 workforce software applications.