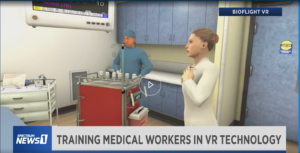

Medical Staff Using Virtual Reality for Lifelike Training

In 2015, chief creative officer Rik Shorten saw an opportunity to use newly developed virtual reality technology and 3D animations in the medical field.

“They can select one of these codes and go through it and they can work as an attending and they’ll have a whole team in front of them virtually and they can do this anytime, anywhere,” Shorten said. Bioflight VR is based in Akron, but the company works with hospitals, universities and medical device companies across the country, including hometown Akron Children’s Hospital. Shorten said the COVID-19 pandemic has brought into sharp focus the need for distance learning, remote training and virtual training.

“The schools are struggling to get the nurses in training their clinical hours. And so the states have moved quickly to recognize XR technologies as perfectly adequate substitutes for in-clinic training. And so this has moved that conversation forward much faster,” Shorten said.

Bioflight VR business director Pauly Suchy said the company recently teamed with Case Western Reserve to develop an application on physician empathy training.

“A 30-minute experience but it spans over the timeline of a month where they’re experiencing all the financial, social, emotional and physical burdens that patients typically face. But it’s also, a good example of how to use this technology to standardize that learning experience so they can deliver better care,” Suchy said.

Both Shorten and Suchy said 12 hospital systems and 1,000 ER doctors currently use their platform. Their goal is to expand that 10-fold in the coming years. They said they know the access to quality health care resources in Ohio can make it possible.

“The idea of a small company with limited resources, we need to get to the right people quickly. And the access here is different. It’s afforded me so many other freedoms than trying to make a small company work in Los Angeles,” Shorten said.

For more information, visit the BioflightVR website.