Companies that trade in food products are held to some of the highest regulatory standards. With globalization ongoing and a higher demand than ever for variety and niche products, companies find they need to expand the mobility of their services. They must also broaden their product choices without missing a beat when it comes to quality.

Augmented reality (AR) and virtual reality (VR) have emerged as unlikely allies in that quest. These technologies are already having a positive impact on food and worker safety in the industry.

Improves New Employee Training

Onboarding and training new employees is a costly and time-consuming endeavor in any industry. Moreover, failure by companies to impart the necessary skills, and failure by employees to retain them, can have ghastly consequences. Errors on assembly lines may result in faulty products, recalls, worker and customer injuries, and worse.

The stakes in the food and beverage sector are just as high as they are in other labor- and detail-oriented industries. VR provides an entirely new kind of training experience for employees, whether they’re working on mastering their pizza cutting technique or brewing the perfect cappuccino. Other times, “getting it right” is about much more than aesthetic appeal and immediate customer satisfaction.

Animal slaughtering and processing facilities represent some of the more extreme examples of potentially dangerous workplaces in the larger food and beverage industry. Between 2011 and 2015, this U.S. sector experienced 73 fatal workplace injuries. Excepting poultry processing, 2015 saw 9,800 recordable incidents in animal processing, or 7.2 cases for every 100 full-time employees.

Some adopters of VR-based employee training claim that virtual reality yields up to an 80% retention rate one year after an employee has been trained. This compares extremely favorably to the estimated 20% retention rate of traditional training techniques.

Training via VR headset can help companies get new hires up to speed faster in a safe, detailed and immersive environment. Food processing and service are high-turnover employment sectors. The right training technology can help workers feel better prepared and more engaged with their work, potentially reducing employee churn.

Helps Eliminate Errors in Food Processing

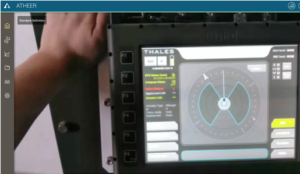

Augmented reality is already demonstrating great promise in manufacturing, maintenance and other sectors. For instance, an AR headset can give an assembly line worker in an automotive plant detailed, step-by-step breakdowns of their task in their peripheral vision through a digital overlay.

The same goes for food and beverage manufacturing. AR headsets can superimpose a list of inspection or processing tasks for workers to follow as they prepare food items in a manufacturing or distribution facility.

In 2018, there was an estimated 382 recalls involving food products. Augmented reality alone won’t bring that number down to zero. However, it does help reduce instances of line workers and inspectors missing critical steps in processing or packaging that might result in contamination or spoilage.

Eases the Learning Curve in Food Preparation

There are lots of food products in the culinary world that are downright dangerous if they’re not prepared properly and by following specific steps. Elderberries, various species of fish, multiple root vegetables, and even cashews and kidney beans can all induce illness and even death if the right steps aren’t taken to make them fit for consumption.

In early 2019, inspectors descended on a Michelin-starred and highly respected restaurant in Valencia, Spain. The problem? A total of 30 patrons reported falling ill after eating at El País, one of whom lost her life. Everyone reported symptoms similar to food poisoning.

The common element in each case appeared to be morel mushrooms. These are considered a luxury food item, but failure to cook them properly can result in gastric problems and worse. Augmented reality could greatly reduce the likelihood of incidents like this in the future by providing ongoing guidance and reminders to new and veteran chefs alike, without taking the bulk of their attention away from work.

Brings New Efficiencies to Warehousing and Pick-and-Pack

Consumers around the globe are getting used to ordering even highly perishable foodstuffs over the internet—and there’s no putting that genie back in the bottle. Amazon’s takeover of Whole Foods is an indicator of what’s to come: Hundreds of freezer-equipped and climate-controlled warehouses located within a stone’s throw from a majority of the American population.

Ensuring smooth operations in perishable food and beverage supply chains is a major and ongoing struggle. It’s not just a practical headache for companies—it’s something of a moral imperative, too. The World Health Organization finds that around 600 million individuals worldwide fall ill each year due to foodborne illnesses.

Augmented reality won’t completely solve this problem, but it may greatly reduce a major source of potential spoilage and contamination: Inefficiencies in picking and packing operations. Order pickers equipped with AR headsets can:

- Receive visual prompts to quickly find their way to designated stow locations in refrigerated warehouses after receiving refrigerated freight.

- Locate pick locations more efficiently while retrieving single items or when they already have a partial order of perishable goods picked.

In both cases, the visual cues provided by AR help employees navigate warehousing locations much more quickly and efficiently. This substantially lowers the likelihood that food products are stuck in limbo in unrefrigerated areas, potentially coming into contact with noncompliant temperatures or pathogens. The FDA recognizes mispackaged and mislabeled food products as a major public health risk.

For food and beverage companies, AR should be a welcome development and a worthy investment. FSMA recognized that 48 million Americans get sick each year from compromised foods. The act required these entities to be much more proactive in drawing up prevention plans for known sources of contamination and to be more deliberate in standardizing their processes for safety’s sake.

AR and VR Boost Food, Worker and Customer Safety

Augmented and virtual reality may seem like an unusual ally in an industry where most consumers are primarily focused on the aesthetic and sensory aspects of the experience. However, there’s a whole world that lives and dies according to the speed and attention to detail of employees and decision-makers alike. Augmented realities, and entirely new ones, point the way forward.