Keen Research Brings the Power of Speech Recognition to AR

The project will initially use Vuforia Studio technology to overlay live data – taken from the ThingWorx® industrial platform – to various points of the facility, so that operators moving around will be able to make informed decisions on changes to casting and melting lines or troubleshoot issues before they happen.

It is anticipated that Augmented Reality will make it easier for staff to hae the right information at exactly the right point they need it, whilst the use of HoloLens and RealWear glasses will mean the individual has both hands free to complete tasks.

This project will contribute to the sector’s longer-term desire to move towards a net zero steel works by 2050 and is part of the £22m PRISM steel and metals sector research and innovation programme being delivered by the Materials Processing Institute with funding provided through Innovate UK, part of UK Research and Innovation.

“The successful implementation of digital technologies has the potential to save tens of £millions every year,” explained Chris Oswin, Group Manager of Digital Technologies at the Materials Processing Institute.

“We are taking responsibility for exploring IIoT platforms and AR and working out how we can get the most out of them in a live steel plant, learning from testing and trials to identify best use cases.”

He continued: “This means we absorb a lot of the time and remove the initial expenditure that could act as a barrier to entry for companies in our industry, hopefully encouraging digital adoption as we will have proved it works and how it can be applied to businesses.

“PRISM is guided by a team of industry leaders on our Industrial Advisory Board, including the Aluminium Federation, British Manufacturing Plant Constructors’ Association, British Steel, Celsa Steel, Liberty Steel, Outokumpu Stainless Steel, Sheffield Forgemasters, Swansea University, Tata Steel and the UK Metals Council.”

The Materials Processing Institute has a long-term relationship with PTC, with the latest project following on from the introduction of ThingWorx as part of the £10m programme to explore how digital technologies can be implemented in brownfield manufacturing sites.

In addition to optimising processes and introducing new efficiency improvements, Augmented Reality will also be used to capture some of the traditional skills in the sector that could be lost if the knowledge of older workers is not retained before they retire.

This will be achieved by using PTC’s Vuforia ® software, with Vuforia Expert Capture allowing operators and technicians to film their daily tasks in step-by-step instructions, in situ of when and where they do their work.

This will be uploaded to ‘the Cloud’, which can then be accessed by new starters or people switching roles, using HoloLens or RealWear to get a real hands-on experience, or other devices such as mobiles, tablets or on desktop computers.

Furthermore, for problem resolution and live ‘on the job’ support, there is Vuforia Chalk. Using mobile devices, digital eyewear or seated at a desk – experts can connect with on and off-site employees and customers and collaborate in real-time. It combines live video, audio and the ability for remote and local participants to annotate their live shared view and mark-up the real-world environment.

“If we don’t act soon, we stand to lose so much knowledge from the industry and AR gives us a cost effective and easy way to retain skills and experience in a virtual library for generations to come,” added Chris.

“Working closely with PTC’s experts, we can tailor how we capture information, footage and skills in what is a very demanding and intense environment. We believe we’ve got the initial framework to start the roll-out and will continue to adapt the processes as we understand more about how digital technologies can play a role.”

David Grammer, general manager for UKI for PTC, went on to add: “Covid-19 has definitely thrust the digital thread into the spotlight, but there is still a resistance to adoption due to a lack of awareness of how it will deliver a genuine business benefit.

“This project with the Materials Processing Institute gives an entire sector the opportunity to explore how AR can be applied and developed in a real live steel plant without the potential disruption and cost of trying it in their own facilities.

“Businesses will be involved in the roll-out and informing some of the test cases and our team will be on hand to support experts at the Institute to get the most out of our technology and software.

“The end goal is that we will have proven business cases on how steel and metals companies can optimise processes using Augmented Reality and live data, not to mention protecting vital skills for the steel workers of the future.”

PTC, which has bases in the UK and Ireland, provides a host of technology solutions to help industrial companies create value for themselves and the rest of the world.

This is achieved through a combination of Augmented Reality, Industrial IoT, Product Lifecycle Management and CAD solutions.

Through the use of Area Targets, industrial organisations can create AR interfaces within their facilities to enable employees to better engage with machinery and understand how the environment is being utilised.

More information can be found here https://library.vuforia.com/features/environments/area-targets.html

PTC says that with support from Matterport and Leica 3D scanners, along with NavVis’s indoor mobile mapping systems, Area Targets users can generate “photorealistic, survey-grade digital twins, empowering them to create digital canvases of spaces such as factories, malls, or offices for advanced spatial computing applications”.

As one of the leading emerging technologies, spatial computing powers digital twin renderings to support the activities of machines and people, as well as environments in which they operate.

When deployed across the industrial enterprise, spatial computing enables seamless interactions between employees through AR, enabling companies to close the loop on performance management, improve machine learning capabilities with spatial analytics, and optimise design and factory floor operations,” notes PTC.

“Vuforia Engine Area Targets is a one-of-a-kind solution for large, persistent AR experiences,” said Mike Campbell, Executive Vice President and General Manager of Augmented Reality, PTC.

“Whether users are looking to add navigation to their office building or view in-context data on a factory floor, Area Targets is the answer. We’re pleased to be expanding such a key capability and component of PTC’s spatial computing vision.”

The release of Vuforia Engine Area Targets marks the second Vuforia offering to deploy spatial computing in the form of area targets within the industrial setting, the first being the Vuforia Spatial Toolbox platform.

Combined with the Vuforia Chalk, Vuforia Expert Capture, and Vuforia Studio AR products, the Vuforia AR Enterprise Platform provides what PTC says is a “robust set of offerings that enables users to increase workforce safety and efficiency, improve customer experiences, and reduce costs”.

As the Head of XR at PwC UK, Jeremy Dalton saw a fundamental problem in the marketplace: too many enterprises had misconceptions about – or simply didn’t understand – the tremendous potential of AR and VR to transform their businesses. So, Dalton took it upon himself to get the message out.

The result is his new book, Reality Check. Reality Check dispels common myths about AR and VR and details how business leaders can integrate immersive technologies into their organizations to deliver more efficient, impactful and cost-effective solutions. Dalton backs up his argument with compelling case studies from organizations such as Cisco, Ford, GlaxoSmithKline, LaLiga, and Vodafone.

AREA Executive Director Mark Sage hosted a podcast with Jeremy Dalton recently to discuss the book and its findings. Go here to hear their conversation. To order a copy of Reality Check and receive an AREA 20% discount, go here and enter the discount code AREA20 before March 5, 2021.

When AREA member Augumenta participated in an AREA webinar about implementing AR on factory shop floors recently, we thought it would be worth catching up on the company and its activities. So we spoke the Eve Lindroth, the company’s head of Marketing Communications. Here’s our conversation.

AREA: Augumenta has distinguished itself as a leader in industrial shop floor uses of AR. To what do you attribute your success so far?

Lindroth: We have a large number of big and well-known industrial companies as our clients, and within these projects, our solutions have been adopted with very few changes. That tells us that we are taking the right approach to developing solutions for the industry. Our clients also praise the ease-of-use of our applications, and appreciate that there is no steep learning curve to start using them. Quite the opposite, they are considered easy to learn.

AREA: What’s a typical Augumenta client?

Lindroth: Most of our business is outside Finland. We have many manufacturing customers in France and Germany, for example, such as Siemens. We also have a presence in Japan and Taiwan which is important considering our focus on the Asian markets and the key customer projects we have ongoing there.

A typical client is a larger industrial company that is active in developing their operations – or during the pandemic, companies that are simply looking for the most efficient and practical ways to keep operating.

AREA: Speaking of that, in October, you announced a partnership with IISI of Taiwan. Tell us about the partnership, its goals, and its progress to date.

Lindroth: IISI is a system integrator and they have a very strong customer base in the fields of manufacturing and government. In our partnership, Augumenta acts as a technology/applications provider and the IISI experts do the final customization and integration with the end customer’s backend systems. Both companies can focus on their key strengths: we on the cutting-edge AR technology, and IISI on developing and managing the overall systems.

We started working together in the springtime and we have finalized all the customization needed for the end customer, a major semiconductor factory in Taiwan. We continue working in close cooperation with IISI and believe we are in a good position to advance enterprise AR in Taiwan together with them.

AREA: What do you see as the most significant barriers to AR adoption, and what is Augumenta doing to overcome them?

Lindroth: We have seen in many pilot projects that the organization has identified the problem they are looking to solve with a pilot, but for example, there are difficulties in defining the current status with an accurate number. For example, there’s downtime – how much there is and which factors exactly are causing it? That can be hard to come by. Another issue is user acceptance, but that can often be tackled by involving the people in planning the solutions from an early stage.

At Augumenta, we’re working to address those issues. For industrial pilots, for example, we created a simple checklist, just to remind the project managers and team leaders responsible for the pilot to consider the factors we have learned to be essential for an AR pilot’s success. These are related to things like target setting, planning together with your people and getting them involved throughout the process, or measuring the results. The checklist is available on our website.

AREA: What can we expect from Augumenta in 2021?

Lindroth: In the future, we believe that discrete industrial AR applications will become more integrated solutions. That means, for example, that there aren’t separate apps for alerting a user and guiding a user in tasks. There will be one solution that can do all of this – without the end user even noticing that there are many use cases included in the app. At some point, things like AI will make the end user’s job even easier by guiding him to the right data or expert automatically, for example.

A key success factor in such a solution is usability. Apps have to integrate seamlessly and be simple and intuitive to use independent of the use case at hand.

The pandemic has meant growth in demand for our services along with our clients’ need to find new ways to do things. In 2021, you’ll see closer integration of our apps. We’re working with new app features that are enabling efficient and sustainable working methods in the new normal. We’ll keep you posted with the latest developments during 2021.

AREA: Finally, how has Augumenta benefitted from its membership in the AREA?

Lindroth: The AREA has provided us with access to research, and there have been some great and very interesting research projects completed. We have also made many new contacts within the ecosystem via the AREA, and it’s always great to see and hear what’s going on with other ecosystem members. The AREA updates its social media channels very actively, and we appreciate the visibility they provide us.

The coronavirus pandemic has forced many organizations to reconsider how well-equipped they are to deal with business disruptions that require more remote work. That’s especially true for industrial companies that succeeded pre-COVID through optimized supply chains and manufacturing processes and specialized employee skill sets.

AREA Executive Director Mark Sage recently spoke with Umar Arshad, Head of Growth for AR Products at PTC, to discuss how more organizations will now leverage AR to maintain business continuity and build resiliency.

Watch the discussion in the Video below:

The AREA seeks to receive proposals for a funded research project that will examine and capture in a report the current status of 5G in enterprise environments, assessments of the risks and opportunities of using 5G technologies for AR use cases, and areas for future research and potential investment for AREA members. The project will also deliver tables containing objective, vendor-neutral information about current component costs, product and service offerings, past and current trials, proof of concept projects and guidelines for AREA members.

Organizations with relevant expertise in the research topic may respond to the invitation on or before 12 PM Eastern Daylight Time on February 10th.

Industry Context for the Research

Investments in 5G are fueled by the potential for new low-latency, high-throughput network technologies to reduce or remove barriers to implementation of new and powerful use cases. By providing connected devices and machines access to high performance computing and other limited and costly resources, 5G networks will significantly expand and lower the cost of use of powerful computing hardware and software, data sets and other services (e.g., privacy, security, localization and other artificial intelligence-based platforms).

Telecommunications companies around the world are heavily promoting 5G technology for delivering AR for entertainment and other consumer-facing services. The 5G-based services will be provided by network operators, some of whom are partnering with AR device and software providers to offer solutions to enterprise customers.

Managers of large enterprise IT organizations are aware of the emerging 5G networks and components, including 5G-ready wearable and mobile devices, but many questions remain to be answered prior to the introduction of these in an enterprise infrastructure. Before AREA customer segment members begin testing AR over 5G in their facilities, they need deeper understanding of key concepts of 5G, and the requirements, opportunities or benefits 5G could bring.

Before AREA provider segment members begin evaluating and planning for 5G-enabled product or services to offer to their customers, they must build out 5G expertise internally or partner with companies that have 5G offerings.

Project Goal

The AREA seeks to provide its members with knowledge about the current status of AR and 5G for enterprise, and actionable information which members can use when planning their AR and 5G strategies.

Fixed Fee Project

The AREA Research Committee budget for this project is $15,000. Organizations interested in conducting this research for the fixed fee are invited to submit proposals.

More information

Full information on the project needs, desired outcomes and required components of a winning proposal, including a submission form, can be found here.

If you have any questions concerning this project and the AREA Research Committee, please send an email to the Research Committee.

In this latest AREA Thought Leaders Podcast, AREA Executive Director Mark Sage poses these questions and more to Stuart Thurlby, CEO of Theorem Solutions, a UK-based company that has provided solutions to the world’s leading engineering and manufacturing companies for more than 25 years. As the leader of a firm that helps companies extract greater value from their 3D CAD assets, Mr. Thurlby understands the biggest challenges companies must overcome to deploy AR/XR successfully.

Don’t miss this must-listen, 15-minute conversation filled with insights into how to get started in Enterprise XR.

You can listen to the Getting started in Enterprise AR podcast here.

View The AREA’s other podcasts, videos and webinars here.

AREA: Tell us about your background in AR at Toyota.

Kleiner: I started almost three years ago. I was working at our headquarters, so my interest in AR was more around marketing and sales than engineering and design. I was convinced that AR was going to be the next big thing in marketing and I wanted Toyota to get ahead of the market.

We made a couple of prototypes that never made it past the prototype stage but got some good reviews. Then COVID hit and everyone was saying, “We’re in a touchless society now; how do we sell?” Well, this is how you sell. As a result, what was a part-time hobby job for me is now full-time. What I’m trying to solve now is how XR fits in at every stage of the customer journey. We’re trying to educate brand-loyal customers that we’re cutting edge and that there are some Toyota vehicles coming out that you can experience at home without visiting a dealership. We’re then trying to track that through to a sale.

A lot of this is about customer education. They don’t know, for example, how Toyota Safety Sense works. They don’t know all the features we put into the vehicle. So our goal is to educate them and “wow” them at the same time – which we hope leads to a sale. Once the sale is made, how do we do the “care and feeding” afterwards? We already have a prototype of an AR owner’s manual, which went over really well – and also reduces costs because there’s no printing required. On our first project, the Lexus AR Kit, we found we could save $11 million a year on shipping and handling of owner’s manuals.

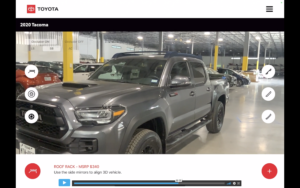

Once we’ve made the sale and delivered the owner’s manual, the next step is selling accessories – and that’s the other product I’m working on right now. We want to be able to capture the buyer’s car – not a cartoon, but a real image – and fly in some accessories to show them how they can customize their vehicle to look better and perform better.

That’s where we’re going. We’re trying to follow the full customer lifecycle.

Our first proof of concept, as I mentioned, was the Lexus AR Kit. It started out as a training platform for dealership personnel but then we modified it to train people on how to use their vehicles. The second pilot we did was a Virtual Showroom. Users can plop the car down at scale in their driveways, then approach it and look inside the vehicle without having to go to the dealership. We completed that in mid-September. The third pilot we’re working on is for accessory sales. The target product is the Tacoma, our smaller pickup truck, which is the most customized of our vehicles. We believe we can increase Tacoma accessory sales by $5 million. If that’s successful, we’ll roll it out to our other highly-customized vehicles.

I’m also tangentially involved in some training work at our manufacturing plants. Since people can’t come to a classroom anymore because of the pandemic, we’re training them remotely using HoloLens through our partnership with Microsoft. Some of the early results are just phenomenal. We found that we could take training from 13 days down to two days. Retention is better and quality is up. It’s been great for both new hires and for reskilling existing workers to take on new tasks.

AREA: What AR software and tools are you using?

Kleiner: On the training side, it’s all Microsoft HoloLens. For marketing and sales, we don’t have an AR studio, so we’re working with an outside vendor called Groove Jones and it’s all custom.

AREA: Tell us about your experience trying to champion this technology in a corporate setting.

Kleiner: I spent a lot of time trying to educate folks, telling them this is not a toy, this is a true tool that belongs in the enterprise and should be part of the customer experience. And many people basically said, “That’s nice, but we’re going to keep doing things as we have.” Once COVID hit, those same people realized we couldn’t keep doing things the way we always had. I’m in demand now!

AREA: So what’s next for you?

Kleiner: Right now, we’re focused on bringing these current proofs of concept to fruition. If those work out well, we’ll expand to other projects. The AR approach is ideal for demonstrating things that aren’t clear in the owner’s manual – for example, how to install an infant seat in the car. That’ll probably be in the next iteration of the AR owner’s manual project.

The idea of the piece is that Combier hacks the Hype Cycle, observing at each point that very early on, much like the technology’s journey through the Hype Cycle, the customer themself goes through a similar cycle as well. The piece follows the customer journey through the technology trigger, the peak of inflated expectations, the trough of disillusionment, slope of enlightenment and plateau of productivity.

The Hype Cycle

This is the initial phase of any rising technology where the concepts and ideas related to technology take place. No products are launched in the market, and the management is keen on people’s interest.

Following our customer journey metaphor, no attempt to use the technology has happened yet.

In the second stage, the technology is implemented in the market and a lot of publicity happens on both successful and unsuccessful criteria.

Hopes for AR and knowledge distribution skyrocket as key influencers in the customer’s organization get onboard, spawning long-term strategy impacts on whiteboards. It’s in these meetings where the technology is heavily oversold to blue sky futures, and distanced from the practical realities for which they were intended.

This is a crucial phase where many companies fail to alter their products with upgraded versions and [too] few who were successful in addressing problems [have the ability to] continue investing more.

The first results with a customer are in, and they are a bit of a let-down. What happened?! The fair-weather champions in the management team now flip 180 degrees.

At this point, innovation and investment become more important for growth as, companies establish products based on future technology and test them in the real environment.

Now somewhat seasoned, the end users and adjacent teams within the customer learn more about their own use cases and applications for AR.

In the last phase, productivity elevates and deepens its root in that technological field. Products become widely implemented in technology and producers establish quality standards.

Finally, long term productivity improvements set in, however it only experiences a gradual growth in impact because of internal scarcity in AR authoring skills and the difficulty of scaling customization for their use cases.

The author then goes on to explain their approach in terms of the 3 key things that you can do to help a company scale augmented reality faster, more productively, and more legitimately.

These three key topics are then explored in detail in the full blog.